Common Sources of ESD Damage You May Have Overlooked

As we’ve talked about previously, often the sources of static electricity go completely unnoticed. This is because we humans can’t even detect a static charge until it gets up to about 3,000 volts. The problem is that sensitive electronics can be damaged by a charge down in the 100-volt range.

If you’re in the business of manufacturing printed circuit boards or other electronics, you already know how serious a problem electrostatic discharge in the work environment can be. But for the rest of us, we may not recognize just how big of a problem ESD can be, and how much it is affecting our critical devices.

Once you become aware, then you’ll want to start addressing the problem by setting up a static-free zone, or an ESD protected area (EPA).

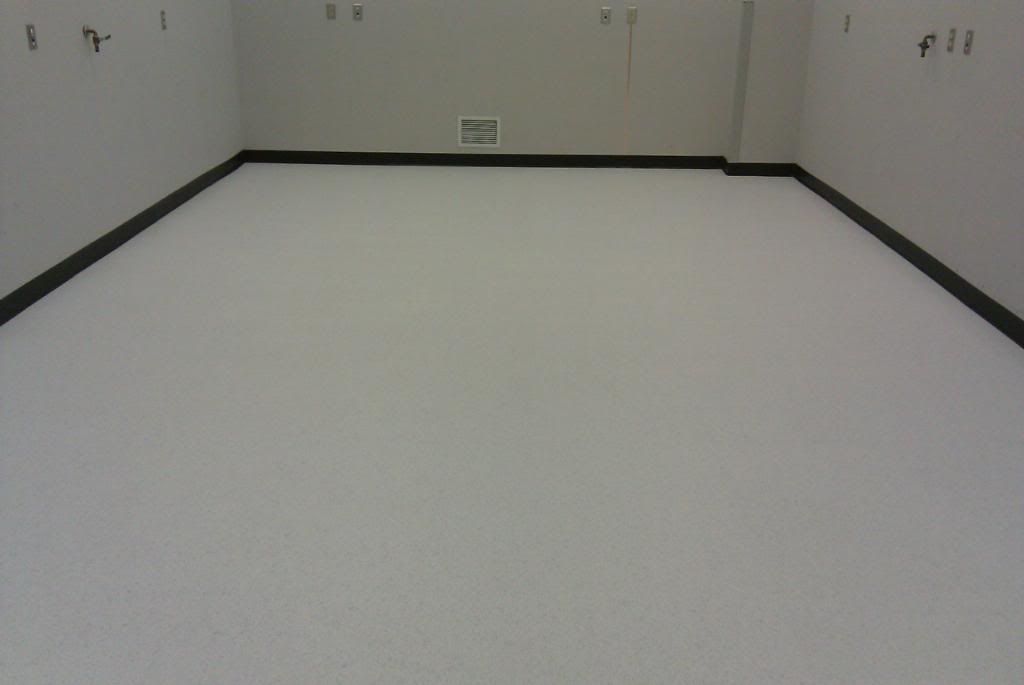

One of the first and biggest areas that you’ll probably begin to address in more critical environments is the flooring itself. Putting in one of the many types of ESD floors will help carry static charges away to ground right through the floor, rather than allowing it to end up damaging your sensitive equipment.

Another method of controlling ESD involves using specially designed ESD shoes that will allow static charges to dissipate.

Using ESD flooring and ESD shoes addresses a major source of static discharge buildup.

But where else do static charges come from?

Believe it or not, the typical work environment is loaded with sources of static electricity. Here are some examples you may not have thought about:

- a typical “scotch tape” dispenser: the tape itself builds up a static charge coming off the roll (which can be up to a few thousand volts!)and the dispenser is usually made up of insulating materials that can build up a charge

- plastic baggies (for components) can have a few hundred to over 1,000 volts of static charge built up on them with simple handling.

- plastic water bottles (or any plastic bottle containing liquid) can build up thousands of static volts of electricity

- any other products made out of insulating, rather than conductive materials (plastic cups, bins, organizers, etc.)

As you can see, often the sources of static electricity are so close at hand, and so seemingly benign, that they’re very easy to miss.

What Can You Do About It?

Bringing static electricity under control at a given workstation can be accomplished using a few simple tools:

- ESD work mats will carry the charge away from any conductive materials you set on them

- ESD grounding straps or wrist straps allow the wearer to stay grounded at all times, preventing the buildup of a static charge on the human body

- The use of monitors and meters will allow for quick and easy measurement of static buildup, which will help identify and eliminate sources of ESD before they become a problem

Need help setting up your ESD protected areas? Give us a call today, and one of our ESD control experts will be happy to provide all the help you may need!