Construction

| DuroStat SMT ESD control vinyl tile and GZ C-2000 conductive adhesive are components of a precision engineered system of advanced static control flooring. Available in SC (static-conductive) and SD (static-dissipative) our tiles contain proprietary encapsulated conductive elements distributed evenly throughout the tile to provide exceptional , electrically consistent, through-tile-to-ground charge decay. Unlike other ESD Tiles these encapsulated conductive elements retain their conductivity for life while providing the electrical assurance you can count on in the most demanding of environments. |

Homogenous Vinyl Tile cross section, note conductive elements throughout thickness

The performance of this solid vinyl tile is not dependent on wear layers, subsurface layers, internal antistats, or humidity and features a lifetime warranty on electrical conductivity! |

Specifications and

Other Properties

| ITEM |

Standard test Method |

ASTM Spec |

Conductive Tile |

Static dissipative Tile |

ELECTRICAL

/ ELECTROSTATIC PROPERTIES

|

|

Electrical Resistance

-Surface to Surface

-Surface to Ground |

ESD S 7.1 (100V)

ASTM F-150 (100V)

NFPA 99 (500V)

DIN 51953 (500V) |

2.5

X 104~106 Ω

(SD: 106~109)

|

2.5 X 104~106

|

106~108

|

<2.5

X 104~

|

<2.5

X 104~

|

Electrostatic Propensity

(=Static Generation) |

ESD

STM 97.2

|

-

|

Less

than 20 volts

|

Less than 20 volts

|

|

Static Decay |

Federal Test Method 101B Method

4046 at 15% Relative Humidity |

< 0.5

sec

|

0.01

sec

|

0.01

sec

|

| OTHER

PROPERTIES |

|

CEN Classification |

DIN EN 685 |

|

Class

34 + 43

|

|

Composition of Material |

ASTM F 1700

Certificate of Compliance |

|

Homogeneous

|

|

Thickness |

ASTM F 386, DIN EN 428 |

as specified ±0.005

in. (0.13mm)

|

1/8",

2mm

|

|

Nominal Sizes |

ASTM F 536, DIN EN 427 |

±0.016

in./lin. Ft (0.4mm/304.8 mm)

|

12

x 12", 24 x 24", 36 x 36"

|

|

Squareness |

ASTM F 540 |

maximum

0.010 in.

(0.25 mm)

|

<0.010"

|

|

Residual Indentation |

ASTM F1914

DIN EN 433 |

average

less than 8%,

max. single reading 10%

|

< 7%

|

|

Flexibility |

ASTM F 137 |

no crack

or break

|

No

crack or break

|

|

Dimensional Stability |

ASTM Fed. Std. No. 501a

Method 6211, DIN EN 434 |

<0.020"/ft

(0.51 mm/304.8 mm)

|

<0.015"/ft

|

|

Resistance to Chemicals |

ASTM F 925

DIN EN 423 |

No more

than a slight change in surface dulling, surface attack

or staining

|

no

more than a slight change in surface dulling, surface

attack, or staining

|

|

Resistance to Heat |

ASTM F 1514 |

∆<8

ave., max

|

<∆E=2.0

|

|

Resistance to Light |

ASTM F 1515 |

∆E<8

ave., max

|

<∆E=6.0

|

|

Static Load Limit |

Modified ASTM F 970-00 |

-

|

2,500

psi

|

|

Smoke Density |

ASTM E 662 |

<450

|

<450

|

|

Flame Spread |

ASTM E 84, NFPA 225 |

<75

|

<75

|

|

Fire Resistance |

DIN 4102 |

|

B1

|

| Critical Radiant Flux |

ASTM E 648, NFPA 253 |

|

>1.08

W/cm2(class I Interior Floor Finish, NFPA

Life Safety code 101)

|

|

Abrasion Resistance |

ASTM D 1044,

CS-10-F Wheel,

500Gm Weight |

|

Cycle

10,000

|

% Gauge Loss

1.60

|

|

| Resistance to Wear |

DIN EN 660-1 |

|

M

|

|

Effect of Castor Chair |

DIN En 425 |

|

No

Damage

|

|

Color Fastness |

ISO 105 B02 |

|

At

least 6

|

|

Standard for Health Care Faculties |

NFPA 99 |

|

Confirms

to the requirements of NFPA 99 in effect at the time

of installation

|

|

Fulfils product requirements |

DIN EN 649 |

|

yes

|

|

Underwriters Laboratories |

UL 779 |

|

Meets

UL Standard

|

WARRANTY

|

| |

Free from defects in Workmanship and materials* |

|

|

Ten

Years

|

|

Conductivity* |

|

|

Lifetime

|

*DuroStat ESD Control Vinyl Tile's Exclusive warranty

is valid only when tile is installed with Ground

Zero's GZ-C2000 Adhesive

Facility Testing

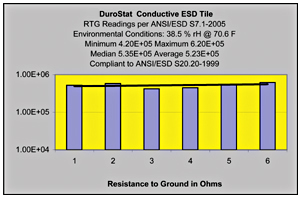

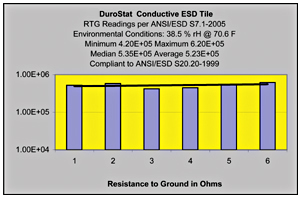

Information below shows our actual "real life" test results after installation at two Facilities (both approximately 70,000 sq/ft each) in separate parts of the Country (one in Mexico, one in California). Testing was performed in accordance with industry accepted standards of EOS ESD 7.1. These floors were installed "on grade" and on cement. Further, the floors were grounded utilizing the advanced parameters shown in How to Ground your new ESD Floor. Your results may vary due to substrate, substrate conditions and environmental conditions prevalent at the testing location.

|

*Tested at a relative humidity > 30%. |

|

|

| Navigation |

|

| Technical Documents |

|

|

|

|

|

The DuroStat

SMT Difference

- Excellent Shine and aesthetics

- Low to no maintenance (no

wax)

- Premier anti-scuff properties

- Excellent electrical properties

- Options in conductivity

- Options in size, thickness

and shine

- Conductive adhesive at NO

charge on large volume orders.

|

to find out.

Have a Question? Get a Quote Now!!

to find out.

Have a Question? Get a Quote Now!!