Physical Specifications:

- Gauge: 0.080 in. (2.0 mm)

- Sheet Width: 6.561 ft. (2m)

- Sheet Length: 65.616 ft. (20m)

- Roll Size: 6ft 6in x 65ft =47 sq yds

(2m x 20m=40 m2)

- Weight: 6.45lbs/sq yd (3.50 kg/m2)

- Tile Size: 23.9 x 23.9in.

(608 mm x 608 mm)

Flame Spread and Smoke

Emissions: - BS; 476 Part 7, 1987: Class 2

- Din 4102: B1

- ASTM E648: Class 1

- AS 1530.3: Flame Spread 0

Light Fastness: >7

In Use Area Classification per EN 685: 34/43

|

Features:

Electrical Resistance:

PolyStat Static Conductive

- PTP: 5.1 x 104 to

2.5 x 106 @ 10 Volts

- RTG: 5.1 x 104 to

2.5 x 106 @ 10 Volts

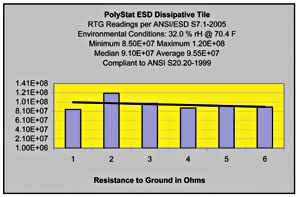

Electrical Resistance:

PolyStat Static Dissipative:

- PTP: 1.1 x 107 to

5.5 x 109 @ 100 Volts*

- RTG: 1.1 x 106 to

8.5 x 108 @ 100 Volts*

- Abrasion Resistance: EN 649:

1996, Group P

Chemical Resistance: PolyStat has good resistance to dilute acids and alkalis.

Chemical resistance charts by shade are available on request

Installation Adhesives: GZ-C2000

or URAS conductive releasable adhesive only.

Static load limit: Per

ASTM F-970

|

| Navigation |

|

|

| Technical Documents |

|

|

|

|

|

|

|

|

to find out.

Have a Question? Get a Quote Now!!

to find out.

Have a Question? Get a Quote Now!!