|

In manufacturing environments

exposed to harsh chemicals and/or severe temperatures,

a vinyl ester or epoxy novalac product is recommended.

Vinyl esters/novalacs are used mainly in the chemical

processing industries, environments that require secondary

containment or any area where concrete is exposed to

chemical attack. Ground Zero's complete product line

of corrosion-control coatings allows us to custom-formulate

a solution for you.

Our commitment to quality and customer satisfaction provides you with a system

that minimizes your cost while providing unequaled performance.

- Secondary Containment Applications

- Combined Chemical, Temperature, Impact & Abrasion

Resistance

- Unsurpassed Chemical Protection

- Complete Floor & Wall Containment Systems

- Seamless Floor-to-Wall Transition

- Sprayable, Broadcast or Roller-Applied

|

Corrosion

Control Coatings

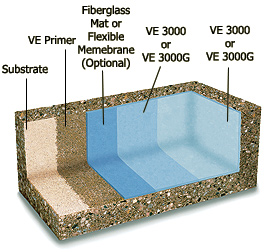

VE-PR Vinyl Ester

Primer

Chemi-Guard VE-PR Primer is formulated for use with vinyl ester systems. It is

a high-elongation primer that will help decrease the curing/thermal stresses

between the topcoat and substrate. VE-PR has a low viscosity, making it easier

to roll, brush or spray than conventional polyester or vinyl ester primers.

VE 3000 and VE 3000G Vinyl

Ester Lining/Coating

Chemi-Guard VE 3000 is an excellent

coating because of its unique combination of chemical

and temperature resistance, impact resistance, abrasion

resistance, and high bond strength to concrete or steel.

It provides excellent chemical resistance against strong

acids, sales and solvents. It is also ideal for applications

involving exposure to thermal shock, harsh chemicals

(such as secondary containment), and outdoor environments.

Its tough, textured, nonporous surface allows repeated

washings and decontaminations.

VE 3000 is available with a graphite

filler (VE 3000G) for spark testing applications or exposure

to hydrofluoric acid. |

Fiberglass Mat and

EPHB CR Mat Saturant or Fiberglass Mat and VE 1000 Mat Saturant

A Fiberglass Mat is used for vinyl ester or epoxy novalac systems that require

crack bridging and/or a smooth, seamless transition from the wall to the floor

coating. Ideal for clean rooms and secondary containment.

JS 3000 Chemical-Resistant Joint

Sealant

This flexible, polysulfide, 100% solids joint sealant is used with the VE (vinyl

ester) systems, providing the required chemical resistance.

EN 7000 Epoxy Novalac

This semi-gloss, orange peel texture coating provides excellent chemical resistance

against strong acids, caustics and solvents. EN 7000 offers good abrasion

and impact resistance, as well as high bond strength to concrete or steel.

Its tough, nonporous surface allows repeated washings and decontaminations.

This coating is ideal for applications requiring secondary containment, as

well as for the chemical processing industry. |